Overview

AN5800 monitoring system is a highly reliable and fully digitalized system developed by ANRY and allows Mod-bus communication. It adopts advanced technology and is designed in accordance with high standard requirement that has been in online operation for a long time, with high reliability, strong ability of resisting disturbance and good compatibility.

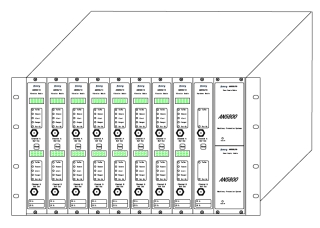

The system has dual redundancy broad power supply as hot backup for each other; each module has independent isolated power module. The arrangement of high-power components (power and relay) on back plug board and signal processing and host machine on front plugboard provides relatively independent property and increases the ability of resisting disturbance, allowing the system to be more stable, reliable and safer when it is in operation, and to meet the requirement of API670 standard.

It has analog signal interface, like 4-20mA and buffer output interfaces, digital communication interface and Mod-bus communication interface. User may monitor a lot of information including the real time running data and status in all channels, alarm setup point, full scale range, alarm status and alarm event list, which allow user to keep an eye on the status of system and control its running.

There are two specifications for the system to meet different user requirements: 19″ standard rack, supporting 18 channels at most, and 14″ small rack, supporting 12 channels at most.

Easy configuration and use

AN5800-CFG configuration control software can perform exact and rapid configuration to AN5800 system, fully improving the manufacturer’s productivity. It displays the real time value and status of all channels of the system in many forms (bar graph, list, curve), readily for configuration and easy for user to monitor the working status of units.

Independent mode or network mode

AN5800 system can work under the independent mode, or together with multiple AN5800 racks through network.

Properties

AN5800 monitoring system:

● Full digitalization design: better stability;

● Plug board design, (19’’ rack with 9 function modules and 18 channels, 14’’ rack with 6 function modules and 12 channels);

● Redundancy design: dual power as hot backup for each other, DPDT relay;

● Isolation design: (each module has independent working power supply, communication bus separated from the power supply), to increase the capacity of resisting disturbance;

● Mod-bus communication interface (bus-based RS-485);

● Panel display: 4-digit display window and LED light indicating status;

● Configuration and calibration on site.

System configuration

Required components

Model | AN5800/90 | AN5800/99 | AN5800-CFG |

Name | Power module | System rack | Configuration software |

System requirements | Required | Required | Required |

Function | System power supply | System bus, rack | System configuration |

Redundant dual power | 19’’ standard rack | Parameter configuration |

Hot backup for each other | 14’’ small rack | Real time monitoring |

Optional components

Model | AN5800/10 | AN5800/20 | AN5800/30 | AN5800/40 | AN5800/50 | AN5800/80 |

Name | Vibration module | Shaft Position module | Speed module | Axis eccentric module | Thermal Expansion module | Key-phase module |

System requirements | Optional | Optional | Optional | Optional | Optional | Optional |

Function | Bearing vibration | Shaft Position | Speed | Eccentricity | Thermal expansion | Key-phase |

Shaft vibration | differential expansion | Over-speed | Key-phase |

|

|

Low frequency bearing vibration | Machine lifting amount | Zero speed |

|

|

|

Throw |

|

|

|

|

|